MelaX Plastics is a newly established yet highly experienced tooling partner, delivering end-to-end plastic injection mold design and development. Leveraging deep industry expertise and a network of qualified tool shops, we provide precision, reliability, and technically advanced solutions.

From concept to ready-to-use molds, we manage the entire engineering, prototyping, and development process—ensuring timely execution, optimized operations, and predictable results. Our approach helps production-focused companies maximize uptime, improve yield, and streamline supplier management, creating measurable operational and financial value.

MelaX Plastics combines fresh agility with proven expertise to be a trusted strategic partner, enabling growth, efficiency, and long-term market success.

Tooling Expertise, Minus the Fixed Costs

We operate as an extension of your organization, providing dedicated tooling expertise without the need to maintain internal specialists or added headcount.

Simplified Execution Model

Centralized coordination across design, tooling, and suppliers removes complexity and improves control over timelines and outcomes.

Dependable Supply Network

Our established relationships with qualified toolmakers and partners ensure consistency, accountability, and reduced execution risk.

Concept-to-Production Solutions

Turning product ideas into manufacturable tooling through structured engineering, validation, and readiness planning.

Tooling Engineering & Program Control

Complete management of mold development programs, ensuring alignment with quality standards, schedules, and production requirements.

Plastic Parts & Commodity Supply

Support for plastic components—from standard commodities to customized parts—through streamlined sourcing and coordination.

Tool Lifecycle & Technical Support

Ongoing assistance to enhance tool performance, extend service life, and maintain production stability.

Supplier Coordination & Governance

Single-point responsibility for toolmakers and vendors to ensure consistency, transparency, and performance.

Collaborative Engagement

Working closely with customer teams to align tooling execution with operational and commercial objectives.

Upfront Manufacturability Focus

Early involvement to convert concepts into production-feasible solutions, reducing downstream challenges.

Full Ownership Across the Chain

Managing tooling activities end-to-end, from initial planning to production handover.

Production Readiness & Ramp-Up Support

Ensuring smooth, on-time start of production with stable output and optimized performance.

Centralized Technical Leadership

A single, accountable team managing all tooling activities on your behalf.

Lean, Coordinated Workflows

Structured processes that reduce internal dependency, management effort, and execution delays.

Performance-Driven Engineering

Focus on durability, repeatability, and production efficiency through disciplined validation and support.

Business-Focused Execution

Every decision is made with the objective of lowering operational burden, improving efficiency, and strengthening return on investment.

To be the preferred partner at the intersection of tooling excellence and packaging supply, enabling efficient, reliable, and scalable plastic manufacturing worldwide.

To support injection molding manufacturers as a tooling development and program management partner, delivering production-ready tools with engineering rigor.

To supply ready-to-use, food-grade plastic packaging solutions that meet performance, quality, and regulatory standards.

To simplify customer supply chains by acting as one accountable partner across engineering, tooling, and packaging supply.

To create sustained value through continuous improvement, disciplined processes, and close customer collaboration.

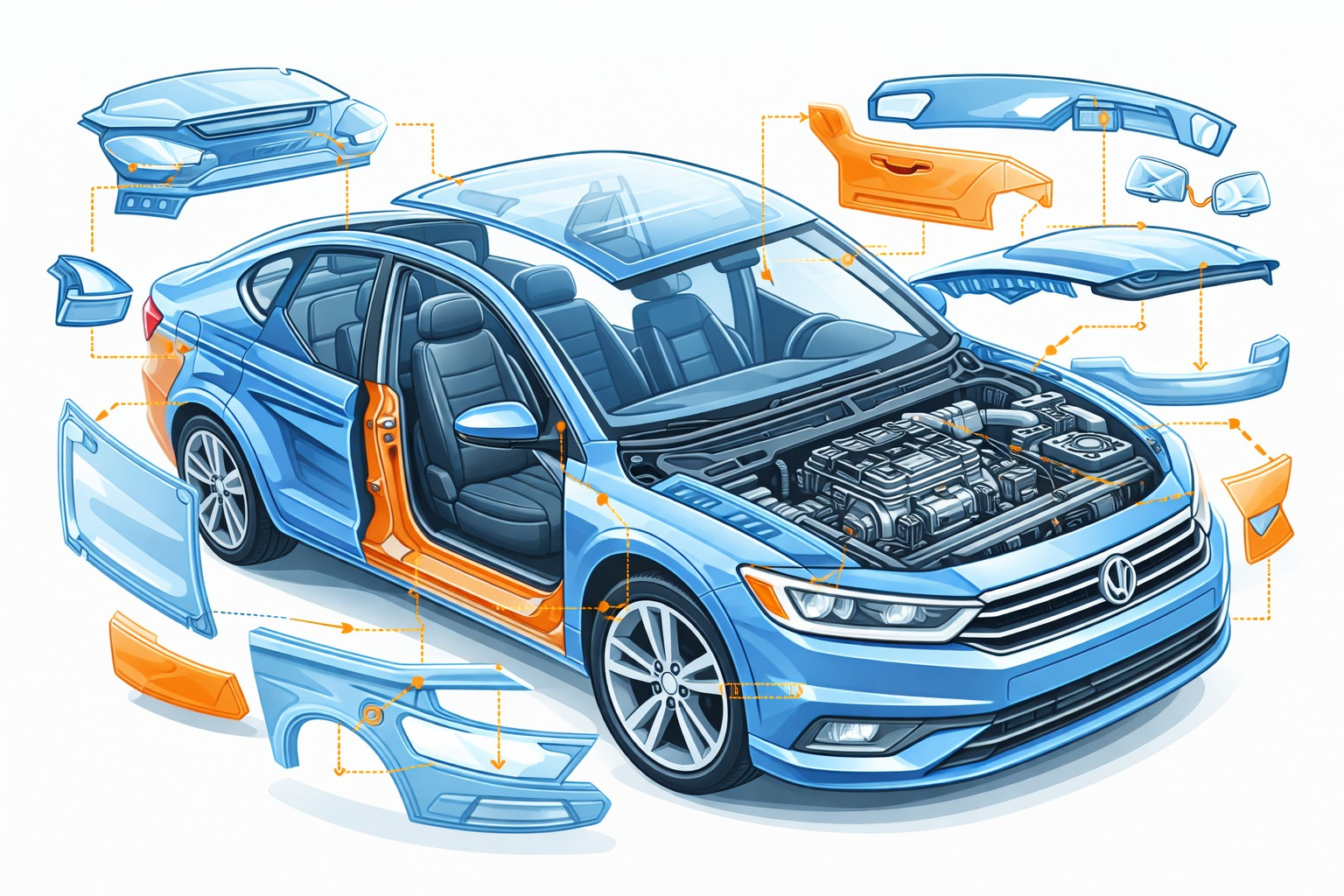

We support automotive plastic component development from design feasibility to PSW and start of production, partnering across feasibility, program planning, tooling development, graining, AAR, and PPAP.

Our experience spans small precision parts to large exterior components such as bumpers, covering Class A and Class B applications—including interior trims, infotainment housings, functional parts, and exterior panels—delivering production-ready tools that meet OEM quality, timing, and performance standards.

Offering comprehensive tooling solutions for FMCG plastic packaging and IML applications, spanning concept evaluation, mold design, development, and production launch.

Expertise includes caps, closures, containers, and IML products, delivering high-performance, production-ready molds engineered for longevity, dimensional precision, efficient cycle times, and dependable mass production.

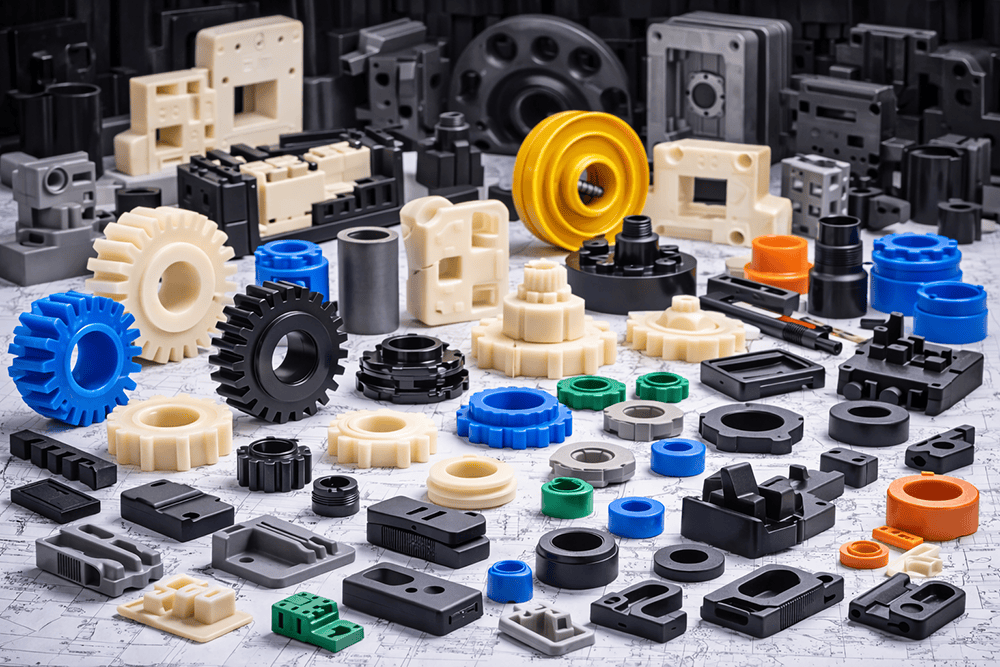

Delivering advanced tooling solutions for industrial and engineering plastics, covering concept validation, precision tooling development, and production ramp-up.

Expertise includes functional components, housings, and structural parts, providing high-accuracy, durable molds designed for consistent performance, efficient cycle times, and reliable large-scale manufacturing.

© 2026 MelaX Plastics. All Right Reserved.

Designed & Developed by  Innov Touch Technologies Pvt Ltd.

Innov Touch Technologies Pvt Ltd.